| GENERAL

Introduction

General Overview

Clinical Services

Research

Teaching

PhDs & Projects

Personnel

IMAGE PAGES

Visual overview

CT, MRI Images

3D Ultrasound

Fetal Studies

Surface Scanner

UCL Hospitals

|

MEDICAL IMAGING GROUP

UCL and UCL Hospital

Surgical Model Manufacturing Services

We can manufacture models of most structures which are of interest

to surgeons. These are made directly from 3D surfaces which may be derived

from CT, MRI or Ultrasound using our own 3d imaging

system. We use a computer-controlled milling process to manufacture

models from blocks of polyurethane foam. The usual application is in complex

bony formations (from CT), for which these models are found to be extremely

useful when complex fractures are being surgically repaired.

These models are made in house, and can be prepared quickly if required.

We can also make models using stereolithography (using an outside service)

if required, but this method is currently rather more expensive.

An

intermediate cost alternative is fused deposition modelling. We now have

our own Stratasys FDM 3000 system and can manufacture high quality models

in ABS plastic in house. This will considerably shorten the time between receiving patient data and having a model ready. An

intermediate cost alternative is fused deposition modelling. We now have

our own Stratasys FDM 3000 system and can manufacture high quality models

in ABS plastic in house. This will considerably shorten the time between receiving patient data and having a model ready.

We are able to accept 3D images in a variety of data formats, from

different scanners, on different media, including the Internet.

The completed models can then be mailed direct to the customer if required.

|

|

|

| The first ABS model made on our new FDM 3000 rapid prototyper.

Slippage of stent graft after endoluminal abdominal aneurysm repair:

note single right renal artery with branch. (more images & movie here)

|

This is an early example of the use of rapid prototyping . A polyurethane

foam model milled directly on our CNC milling machine in 1990.This image

also shows theTitanium cranioplasty plate

custom made to repair the defect. |

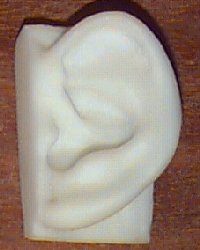

An ABS model of an ear used for prosthesis design and manufacture |

|

|

|

An ABS model of a mandible |

Another early example of the clinical use of RP. This plaster model was made in 1991 by milling two negative mould parts in polyurethane foam and filling the mould with plaster of paris. It shows a compressive fracture of the top of the tibia (knee-joint). This model was a valuable aid at surgery. |

|

Other Applications:

For more information please email Robin Richards, robin@medphys.ucl.ac.uk

|

|